Screen Washing/Reclaiming

fineLine screenPrep post- and prepress equipment

A complete range of post- and prepress equipment that is perfectly targeted for small, midsized and large screen printing companies in graphics, industrial and technical market segments. Completely manufactured in Germany and made entirely of high-grade, stainless steel 1.4301, this robust family of processing machines has enjoyed top ratings from hundreds of customers worldwide. Machine sizes are available from 34” x 47” to 12 ft x 24 ft.

Free-standing or inline machine configurations are constructed for fast and unobscured operator access to the inside of the screen developing, washing, reclaiming and degreasing modular systems. Screens are always processed from both sides simultaneously with Intelligently Applied Automation in mind.

All fineLine screenPrep machines are available with our new and exclusive ePowerWash technology that allows for precise, pre-programmed, electronically controlled and totally flexible water pressure adjustment from 15 – 500 PSI. This unique processing flexibility applies independently to either front or back nozzle bars and for each individual processing pass of the application bridge.

fineLine screenRotoWash – standalone screen washing/reclaiming for industrial and technical screen printing applications

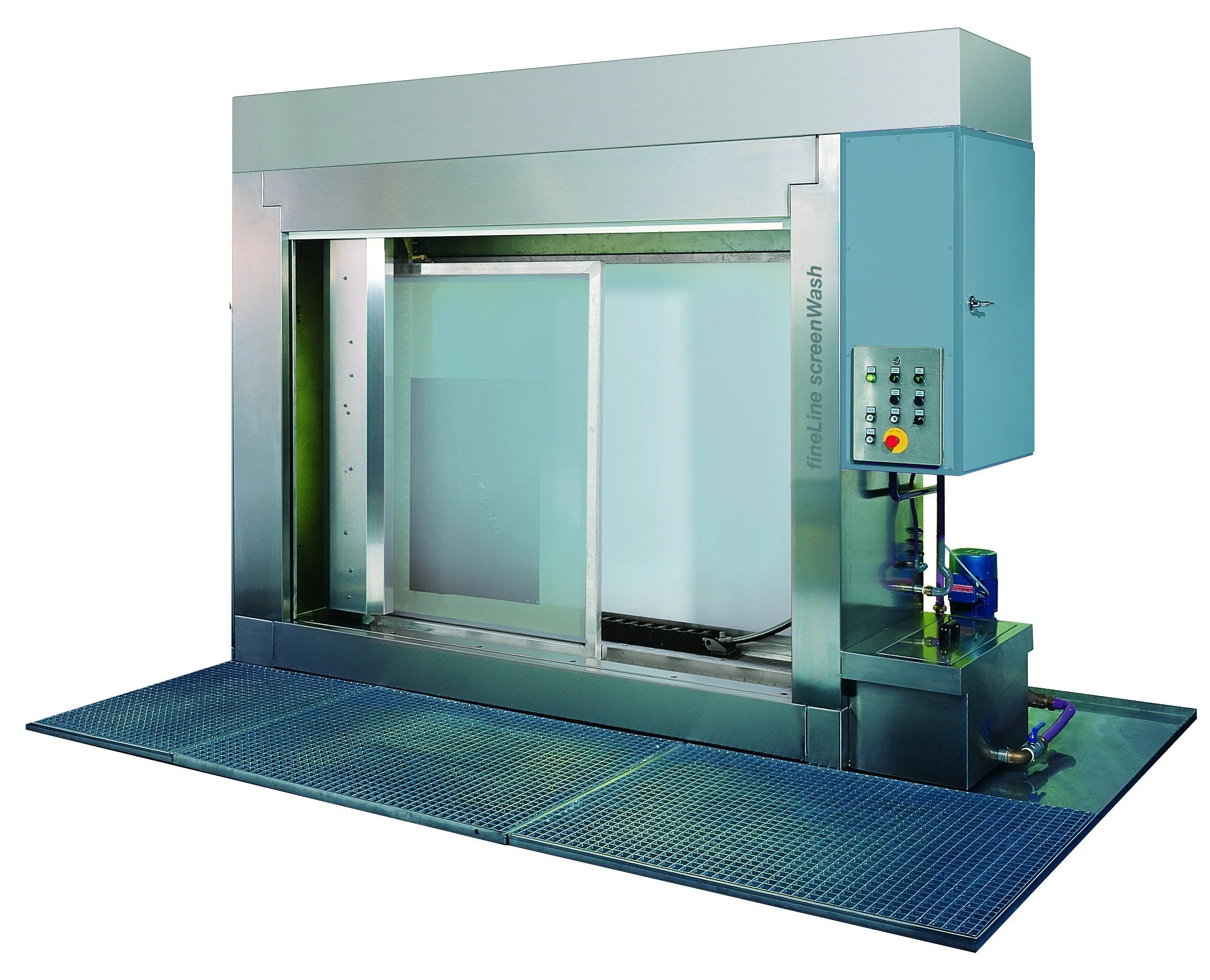

fineLine screenWash – automatic screen washing and reclaiming

The automated self-contained or inline machine configurations are available as screen washing or a combination of screen washing and reclaiming units. The automatic rapid shutter door provides easy operator access to the processing chamber and LED backlit wall allows for immediate quality control.

Enclosed processing chamber protects work space and operators. Intelligently Applied Automatic processing ensures uniformity, consistency, process control and predictability in screen making. Recycling water via a special filtration system and sparingly using fresh water is an environmentally pro-active and money saving approach.

Our new and exclusive ePowerWash technology that allows for precise, pre-programmed, electronically controlled and totally flexible water pressure adjustment from 15 – 500 PSI is part of this equipment. Machine sizes are available from 34” x 47” to 12 ft x 24 ft.

All equipment components except for the electric cabinet are of ATEX explosion-proof execution.

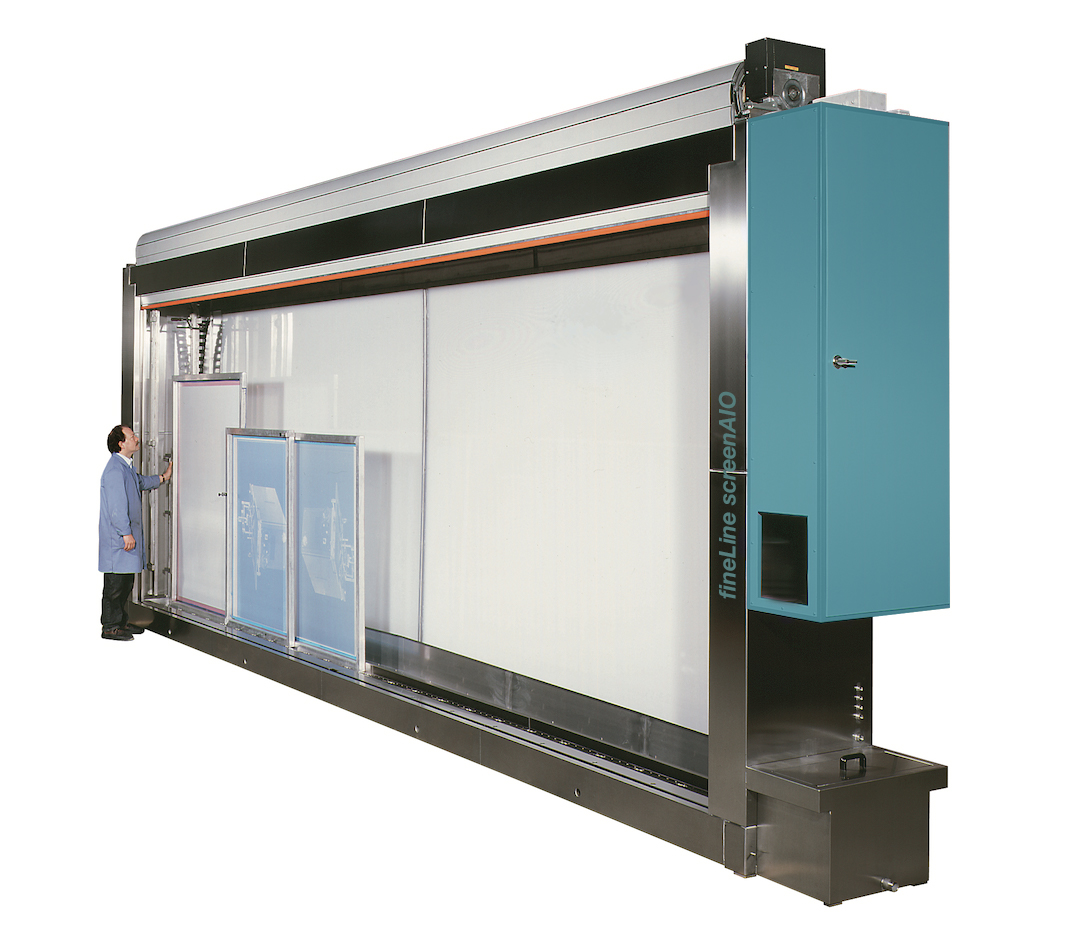

fineLine screenAIO – automatic All-In-One screen developing, washing, reclaiming and degreasing

This compact All-In-One, hermetically enclosed processing system is designed for small and mid-sized screen printing companies that allows for screen developing, screen washing, screen reclaiming and screen degreasing – all in one machine.

The application bridge includes separate front and back nozzle bars for recycled water, fresh water, for each washing and reclaiming chemical, and for degreasing fluid. In addition, for each process there are separate pumps, stainless steel tanks and plumbing assemblies to eliminate potential contamination of the individually protected circuit of controlled application processes.

Our new and exclusive ePowerWash technology that allows for precise, pre-programmed, electronically controlled and totally flexible water pressure adjustment from 15 – 500 PSI is part of this equipment. Machine sizes are available from 34” x 47” to 12 ft x 24 ft.

fineLine screenAIO – standalone or inline All-In-One technology

fineLine screenPrep – various inline configurations for standalone or inline processing